Touchscreen News

5 Facts About Resistive Touchscreen Technology

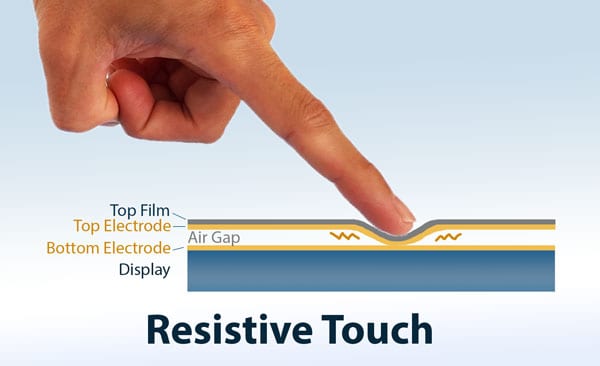

Consists of Multiple Layers

A typical resistive touchscreen panel is made of several layers, including two transparent layers separated by a layer of air or inert gas. These layers are designed to face either so that when the operator presses down on the surfaces, it forces them to make contact; thus, the device is able to identify the point of touch and trigger the appropriate command or input.

Can Be Used with Gloves

One of the great things about resistive touchscreen devices is that they can be operated with or without gloves. This is in stark contrast to capacitive devices, which can only be operated using your bare fingers. So, how can resistive touchscreens support the use of gloves? The answer is because resistive touchscreens identify touch simply by pressing the upper and bottom layers together, whereas capacitive touchscreens identify touch based on the electrical charge produced by the operator. Whether you are using a stylus, gloved finger or bare finger, a resistive touchscreen will function as intended.

Used in Factories and Hospitals

According to Wikipedia, resistive touchscreen devices are often used in industrial factories and hospitals. This is because resistive offers a greater level of resistance to liquids, dirt, dust, debris and other contaminants. While resistive touchscreens aren’t immune to the intrusion of debris, they offer a higher level of protection when compared to their capacitive counterpart.

Used in Video Game Systems

You might be surprised to learn that resistive touchscreens are used in video game systems. Nintendo is particularly fond of the technology, implementing resistive touch in its DS Family, 3DS Family and WII U GamePad.

Contrast

But there are some disadvantages associated with resisitive touchscreen technology, one of which is the lower contrast. Because they have additional reflections created from the extra layers of material, which are separated by air or inert gas, it lowers the contrast.