Touchscreen News

How Capacitive Touchscreen Devices are Constructed

If you keep up with our blog here at En-Touch, you are probably familiar with the two primary types of touchscreen devices: resistive and capacitive. Resistive touchscreen devices rely on pressure to calculate the operator’s point of touch, whereas their capacitive counterpart uses the operator’s own electrical charge to determine this information. Most smartphones use capacitive sensing technology, as it offers greater accuracy and reliability. But how exactly are capacitive touchscreen devices constructed? This is a question that we’re going to answer in today’s blog post.

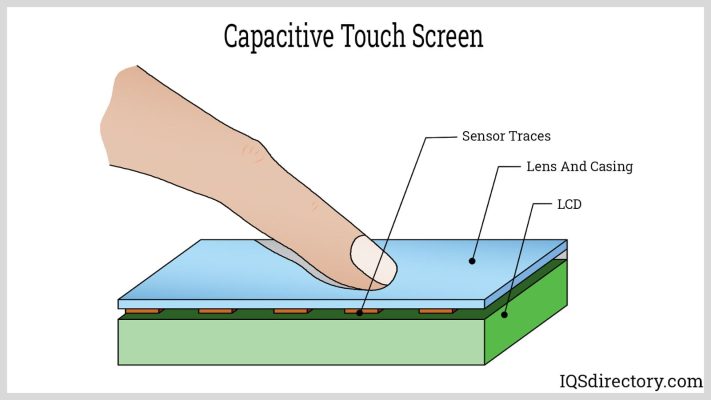

While different device manufacturers use different techniques when creating their capacitive devices, most consist of a few basic components. A typical capacitive touchscreen device has an insulator layer (e.g. glass) that’s coated with a transparent conductor like indium tin oxide. This layer is critical to the overall function of the device, as the layer must act as a conductor to allow the operator’s electricity to flow through it. If the layer is resistive, the operator’s touch will not produce an electrical charge; thus, rendering the device inoperable.

In comparison, resistive touchscreen devices do not require this layer, as they work to identify touch based on pressure. And being that they rely on pressure, there’s no need for a conductive layer. This is why you can operate a resistive touchscreen device with or without a stylus, but you can only operate a capacitive touchscreen device with a bare finger (or special conductive glove or stylus).

According to Wikipedia, the most popular techniques for creating a capacitive touchscreen device involves four layers: the first layer consists of a top polyester coated with a transparent metallic conductive coating underneath; the second layer is an inert “spacer” layer; the third layer is a class layer coated with a transparent metallic conductive coating; and the fourth and final layer is an adhesive layer on the backside of the glass that is used for mounting.

But while capacitive and resistive are the two most common and widely used forms of touchscreen technology, there are other ways to create a touch-sensitive interface. This includes surface wave acoustic, surface capacitance, projected capacitance, mutual capacitance, self-capacitance, infrared grid, acoustic pulse recognition and more. Each of these technologies has its own unique characteristics, along with its own pros and cons. When choosing a touchscreen device, whether for personal or commercial use, you should familiarize yourself with the different touchscreen technologies to determine which one is best suited for your needs.